Ever since GeoStruct’s earliest days ten years ago, NKM Network Services has been one of its strategic partners. That collaboration is now entering a new phase with the One-Fibre project. Martijn Jacobs, Sales Engineer at NKM, updates us.

“Due to the current pace of the rollout in the Netherlands we start a new fibre-optic project about once every two months”

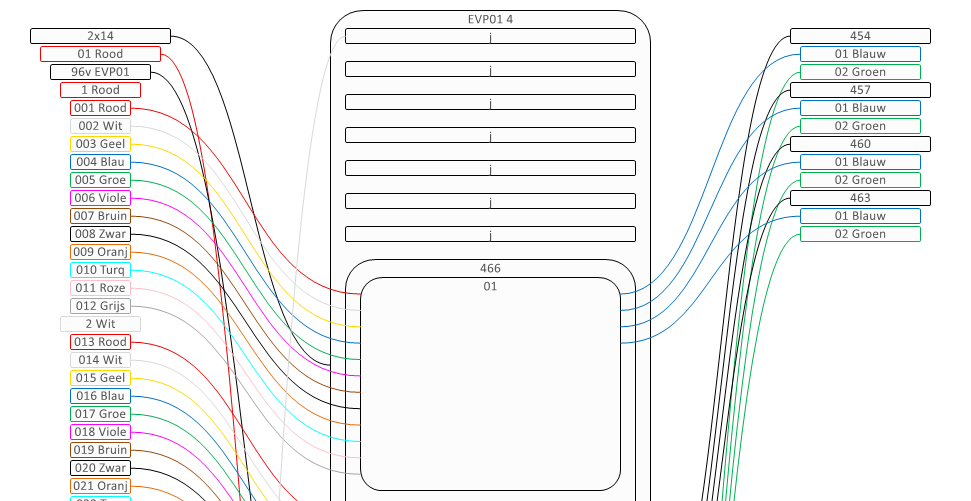

So, what does the one-fibre concept entail? Normally, two optic fibres are used to connect a home. But this alternative approach requires that only one be “lit” – that is, connected to the PoP. Short for “point of presence”, this is the local heart of the network: a node from which fibre-optic cables spread across the neighbourhood. Thanks to the one-fibre system, the capacity required of this network into homes is reduced by 50%.

Martijn lists the advantages. “Firstly, the one-fibre system means that fewer feeder cables are needed for each customer group than with the two-fibre system. That halves the amount of welding work at the final distribution points (FDPs). Secondly, you can cascade the FPDs. That is, you need to use only one fibre-optic cable for two FPDs. Otherwise, they would have to be one-to-one. This allows you to connect a larger area with a single feeder cable. Thirdly, in combination with updated patch panels in the PoP you can handle more customer connections in the same cabinet space.” All this results in efficiency gains, which also benefit the end user because they reduce the cost of their connection.

Support throughout the project

Because the current software is still configured for the two-fibre system, GeoStruct has been working hard to modify it. “That’s a big job,” Martijn admits. “Fortunately, GeoStruct is able to work quickly. They know a lot about software for network construction, and so do we, so in this case one plus one makes three. We’re well on our way: it’s now just a matter of tweaking the final details. Which is going very well, thanks to GeoStruct’s efforts.”

The first step in the design process has already been taken. “We’re currently busy with the civil-engineering design in GeoStruct: where to put trenches, where to bore tunnels. This requires consultation with bodies like local authorities, water boards and [rail infrastructure operator] ProRail. We’ve made a lot of progress with that.” NKM then uses the GeoStruct software to produce the complete design, including welded splice sleeves.

“The GeoStruct platform is supporting the project in various phases,” Martijn continues. “During the surveying phase, routes are studied using our mobile application. The surveyor can make notes in the plan, which the designer can then view and process almost immediately. In the design phase, the desktop application enables us to project a network onto the route almost entirely automatically and to generate reports for the construction team. During construction, the mobile application uses data from a GPS measuring rod to record the actual location of the cables. Finally, the desktop application hands over control of the network to the client’s management system.”

Software to fully simulate reality

“NKM is responsible for the entire process from consultancy to design, from installation to maintenance and management. A project we began recently is special, though, because we’re using the one-fibre concept for the first time. This technology isn’t actually new, but it is a first in the Netherlands for the NKM client. And GeoStruct is providing the design software.”

The one-fibre concept is a significant step forward in the construction of fibre-optic networks. “It takes up less space in the PoP,” Martijn explains. “When a feeder cable with 96 fibres arrives there, a splice sleeve or FDP splits them to reach individual homes. With the two-fibre system, you can serve up to 48 homes. With the one-fibre alternative, the maximum is 96. That represents a huge improvement in efficiency. But there are still two fibres going into the home. The second one is a reserve for possible future use.”

NKM received a request from the client to develop a design based on the one-fiber system. NKM and GeoStruct gladly accepted the challenge. “It’s a question of starting on time,” says Martijn, “so that now we’re ahead of the game. Our client continues to work closely with us, which is great. And it’s wonderful, of course, that they’ve put their trust in us to carry out their first project in this way. It’s covering just over 3,000 homes, so quite small when you consider that NKM has other projects involving up to 20,000 properties. The software enables us to fully simulate the actual situation.”

That is essential, because there is no going back now. “With this new connection concept, you’re making a massive investment which is going to cause all sorts of processes to run differently. And you can’t fall back on the old concept, because you’re putting less hardware into the ground.” No worries, though, Martijn stresses. “GeoStruct has it all in hand.”